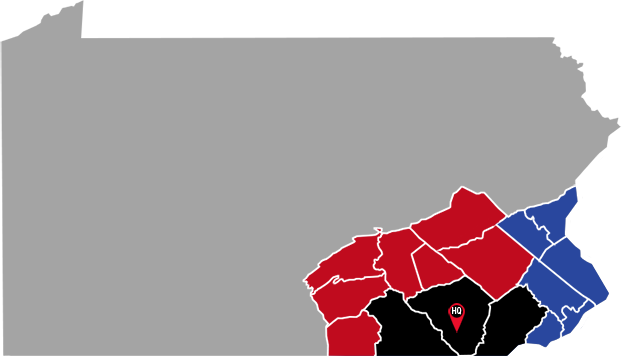

Commercial Painting and Epoxy Flooring Contractors in Pennsylvania

INDUSTRIAL PAINTING : EPOXY FLOORING : COMMERCIAL PAINTING

Pennsylvania is home to some of the most well known brands and companies in the world. And those brands range from sector to sector, covering food production, motorcylcle manufacturing, antiquated coal mining, any many others. And all that productivity requires well maintained plants and facilities, that can keep up with the never-ending production. And here’s why painting and flooring are key components to every facility’s maintenance schedule.

OUR Harrisburg County Contracting Services Include

COMMERCIAL PAINTING, INDUSTRIAL PAINTING, CONCRETE POLISHING, AND EPOXY FLOORING IN PENNSYLVANIA

Pennsylvania ranks as one of the largest manufacturing states in the nation. Home to some of the nation’s largest producers, Pennsylvania hosts a surplus of factories and plants that produces and manufactures some of the most desired products across the globe. From pharmaceutical and food manufacturing, to steel foundries and metal fabrication, to rich agriculture, to some of the most active logistic areas in the world, Pennsylvania has nurtured and developed a very active and dominant economy.

And with the strong presence of manufacturing, there is a strong demand for facility upkeep and maintenance, requiring industrial painting, commercial painting, and epoxy flooring. Industrial painting can help Pennsylvania manufacturers by protecting steel structures from Pennsylvania’s varying seasons, and also offer presentable facilities that attract quality employees and customers. Additionally, the industrial painting in Pennsylvania can help food and pharmaceutical manufactures pass manufacturing regulations.

And the importance of facility maintenance transcends even to the floors, where Pennsylvania manufacturers often request epoxy coatings or urethane cement to cover and protect the concrete. The resinous floor coating helps create a seamless finish that will prevent and discourage insects and rodents from entering the facility. Additionally, these floor additions can add texture, creating a slip resistant surface, helping to keep employees safe.

A majority of these manufacturers reside within the pharmaceutical and food production sector. These sectors are subject to very strict regulations, and require very clean manufacturing. Facilities have to be proactive to prevent contamination from insects and rodents, and ensure that the facility is properly maintained so product isn’t contaminated. Industrial painters and facility painters will take the necessary steps to seamlessly seal the joints and cracks in the walls and floors, and apply enough paint to ensure that there is no flaking or peeling. Areas need to be clean, and joints and cracks need to be sealed.

EPOXY FLOORING IN PENNSYLVANIA

Epoxy flooring in Pennsylvania begins from the ground up. Concrete will create a mighty strong floor in a plant, facility, or warehouse. But it can be vulnerable to chemical exposure or excessive water, or it can become saturated with oil or engine fluids and become a slip hazard. Concrete benefits from its strengths, but it still requires additional care and industrial coatings to maximize its potential.

Because concrete is so porous, it can absorb a lot of liquid. Depending on which liquid it absorbs, the concrete can react negatively to that liquid, and experience damage. If too much water is absorbed into the concrete slab, that water can expand and contract during climate extremes. All of that expansion and contraction causes stress throughout the slab, causing it to lose its strength integrity. The benefit of the epoxy coating is that it will adhere tightly to the substrate of the concrete, sealing the pores and voids, and preventing water from breaching the substrate. If a chemical resistant epoxy coating is applied, then that epoxy floor will prevent chemical from making contact with the concrete, and protect the concrete from deterioration.

Additional benefits that Pennsylvania manufacturing receives from epoxy flooring is slip resistance. Slippery floors are a massive safety hazard in any production or operations area. And one of the many benefits of epoxy coating systems is the opportunity to add slip-resistant aggregate to the mixture. After the epoxy has been applied to the substrate of the concrete, sand or aluminum oxide can be broadcasted into the mixture. That broadcast will seal in the coating, and create an aggressive texture that will create friction between the person’s shoe and the floor.

And beyond that safety and preservation of concrete, epoxy flooring can offer decorative top coats and finishes, helping to enhance the room for these Pennsylvania facilities. Epoxy flooring material can come in many colors, helping to reinforce a color theme or logo of a company. Or, epoxy flooring can be applied in lines, adding organization and directions to the floor.

Overall, epoxy flooring in Pennsylvania provides great benefits to preserving the concrete slabs, protecting the laborers, and enhancing the aesthetic integrity of a facility, plant, or production area.

PRODUCTION FACILITIES IN PENNSYLVANIA

Pennsylvania production facilities produce foods, parts, turbines, pharmaceuticals, coffee, paper, and more. All of this production and manufacturing requires focus, attention, quality control, and attention to detail, in order to fulfill their customers’ expectations. But there is more to a production facility than just the product being produced. There are needs to maintain the integrity and function of the facility. The facility needs to be well maintained and operating; otherwise the product being produced in Pennsylvania can be compromised.

Industrial coatings such as epoxy flooring, epoxy paint, urethane paint, and urethane cement flooring can help protect and preserve the substrate of building material that are holding and supporting these Pennsylvania facilities. Corrosion and deterioration is a the most common cause of failure for steel and concrete. And corrosion and deterioration is caused by water, UV rays, and chemicals. The benefits of epoxy coatings, industrial paint, and commercial paint is that it protects the substrate of these structural materials, preventing corrosive substances from coming in contact with the substrate. Pennsylvania production facilities can expect a longer life expectancy when their facility is properly coated with rust-preventive and corrosion-deterrent industrial paints and epoxies.

Pennsylvania production facilities that produce pharmaceuticals and food products need to do more than just maintain structural components. Their products are vulnerable to contamination, and have routine inspections from the FDA, thus requiring above-and-beyond maintenance and facility upkeep, as compared to other non-consumable production plants in Pennsylvania. Epoxy flooring does an excellent job coating concrete. Concrete by itself is a very dusty product. By installing an epoxy floor overtop the concrete, the dust that can contaminate the consumable product is now controlled. Additionally, epoxy flooring in Pennsylvania production plants can seal and protect creases, cracks, and crevices. These open areas are vulnerable to insects and rodents, which can contaminate the product. By sealing those structural vulnerabilities, the food or pharmaceutical plant in Pennsylvania is more likely to prevent contaminants from breaching its consumable product.

URETHANE CEMENT FLOORS IN PENNSYLVANIA

Epoxy floors can offer a nice coating, decoration, slip-resistance, and chemical resistance to concrete slabs. But sometimes, manufacturing in Pennsylvania needs more than just a 20 mil coating to protect the floor. Urethane cement is an excellent solution for floors looking for more all-around protection. Instead of a 20mil or 20 mil coating, urethane cement uses a trowel application, meaning that more material will be spread over the floor. The end result is often a 3/16” – ¼” urethane cement floor. A floor with this much more girth can offer greater protection from abrasion.

But the urethane cement material offers benefits beyond its thicker application. It is extremely hard, and can withstand heavy traffic from fork lifts and pallet jacks. And its superior hardness can prevent nails or screws from penetrating through the material. It has excellent chemical resistant, making it a great choice for food, pharmaceutical, or chemical manufacturers in Pennsylvania. These facilities need to be cleaned often and thoroughly, which requires very caustic cleaners that can break down dirt, grime, and bacteria that can contaminate product. And not only can urethane cement withstand caustic cleaners, it can also prevent microbial growth.

Urethane cement is a far superior flooring option for manufacturing facilities in Pennsylvania. However, the trade-off for receiving this superior floor is that it is more costly than epoxy coatings.

FACILITY PAINTING IN PENNSYLVANIA

Pennsylvania is home to some of the world’s largest facilities, producing food, pharmaceuticals, steel, agriculture, and more. And often enough, these facilities host flocks of potential clients and customers, looking to buy wholesale. These customers will typically walk through the facility that they plan on buying wholesale product from. When these walk-throughs are common, it is ordinary that a facility will put extra care and attention into the presentation of its facility. Industrial painting, commercial painting, and facility painting in Pennsylvania can include structural steel, corrugated decking, galvanized steel, I-beams, C-channels, and more. When customers walk in and see flaking paint, or dust falling from the ceiling or walls, it’s a strong indicator that the Pennsylvania production facility doesn’t take the appropriate action to ensure the integrity of their product.

INDUSTRIAL PAINTING IN PENNSYLVANIA

Pennsylvania is a large manufacturer of steel. And that steel is often used to construct and build large facilities and buildings. And as strong as that steel is, it is vulnerable to water. Excessive exposure to water can cause the steel to corrode and rust, making the steel unstructurally sound and unsafe for the inhabitants of the building. Industrial painting provides many benefits in Pennsylvania, helping to protect that steel, and other infrastructure material, such as corrugated ceiling, decking, bar joists, I-beams, C-channels, and galvanized steel.

Industrial painting coats the surface of the steel, protecting it from the water. But saying what it does in only 1 sentence doesn’t do the actual process justice. Paint such as urethanes and epoxy offer superior adhesion than standard water based paints. These paints aggressively adhere to the substrate, decreasing the chance of the paint delaminating from the surface. Additionally, industrial paints in Pennsylvania offer a “high-build,” meaning that the more material can be applied than standard paint. The benefit of a “high-build” is that it coats the corners and turns of steel. These corners and turns create weak points in the paint, making it easier for water to break through the coat. The high build helps keep the paint on these weak points, reducing the likeliness of paint failure.

COMMERCIAL PAINTING IN PENNSYLVANIA

Commercial painting in Pennsylvania fulfills 2 major needs: a presentable building and protected substrates. Commercial buildings in Pennsylvania typically need to cater themselves to the public. They need to be clean, orderly, and offer “curb appeal” so that the viewer of visitor can become potential customers. In addition to appeasing customers, the commercial paint in Pennsylvania needs to seal and protect the substrates they are coating. Exterior commercial substrates are exposed to excessive amounts of adverse weather, including rain, sleet, snow, and UV rays. The commercial paint has to offer aggressive adhesion, so it doesn’t delaminate because of these adverse weather conditions. Additionally, it has to offer enough tensile strength to prevent the adverse weather from damaging the coat. And Pennsylvania offers a wide range of adverse weather conditions, so the commercial paint has to withhold a lot of abuse.

POLISHED CONCRETE IN PENNSYLVANIA

Polished concrete has recently become a new flooring option for industrial facilities and plants in Pennsylvania. Their main benefits are the ease of cleaning and maintenance, and the nice commercial presentation they offer. Pennsylvania’s industrial sector could benefit from polished concrete because of how easy it is to clean, while also increasing luminosity of the area. Polished concrete does have it’s limitations: it is not chemical resistant, and the customer runs the risk of having irregular concrete aggregate exposed. If the plant requires chemical resistant flooring, polished concrete would not be a reliable solution, but instead, urethane cement would be the better recommendation.