Floor Joints & Membranes

When it comes to your facilities’ flooring, the details can make a significant difference. By making sure your floor’s joints are properly treated and seeking fillers when necessary, you’ll preserve the look, functionality and durability of your flooring. But more importantly, you’ll keep your facility maintenance budget on track and ensure the overall safety of our workforce.

So if you’ve noticed that your flooring is showing signs of damage in the form of voids, humps or divots, it’s important to address the issue sooner rather than later to avoid workplace accidents and prevent more time-consuming and costly repairs.

If you’d like to work with an experienced contractor who can repair or install new flexible expansion and control joint fillers or membranes, contact PennCoat today. We are dedicated to keeping your facility running smoothly and safely, and we strive to ensure your flooring system is in optimal condition. We can meet with you to develop a plan, prep the area and complete the job with minimal disruption to your operation.

At PennCoat, we offer two types of semi-rigid fillers that are stiff enough to support traffic but that also have low range adhesive and tensile strengths: polyurea and epoxy.

- Polyurea Floor Joints

Polyurea rapidly cures in one hour or less, and it is an effective solution for concrete floors that are not treated with a resinous topper. They are beneficial for food processors and food storage warehouses that require a floor surface that is free of open joints or areas where a bug can enter or hide. On the other hand, polyureas can become very hard and rigid, and they are not color stable. Aside from black, most other colors will amber or discolor in a relatively short period of time.

- Flexible Epoxy Floor Joints

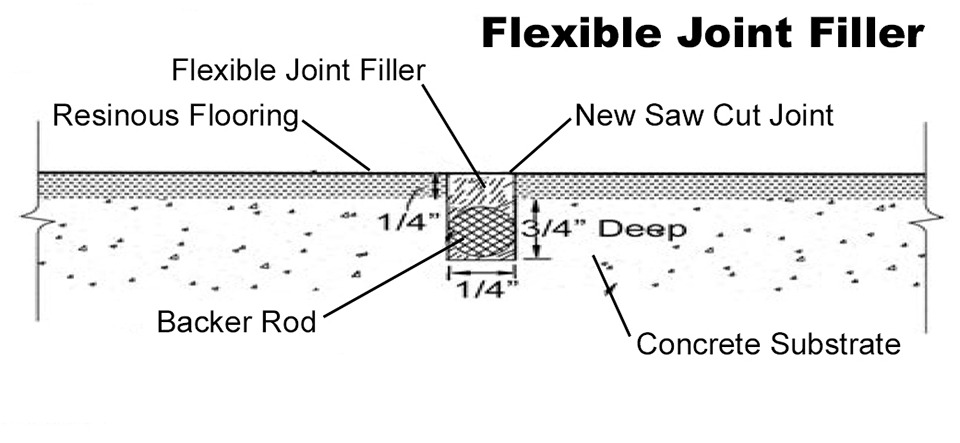

Flexible epoxy systems are a blend of semi-rigid materials that are effective for joints that can move with heavy loads or seasonal changes. They can be tinted to match or complement the existing flooring, can be formulated to have more lateral expansion and are more forgiving when a joint contracts. The downside is that this type of joint filler is more labor intensive to install compared to polyurea joint fillers.

- Rigid Epoxy Floor Joints

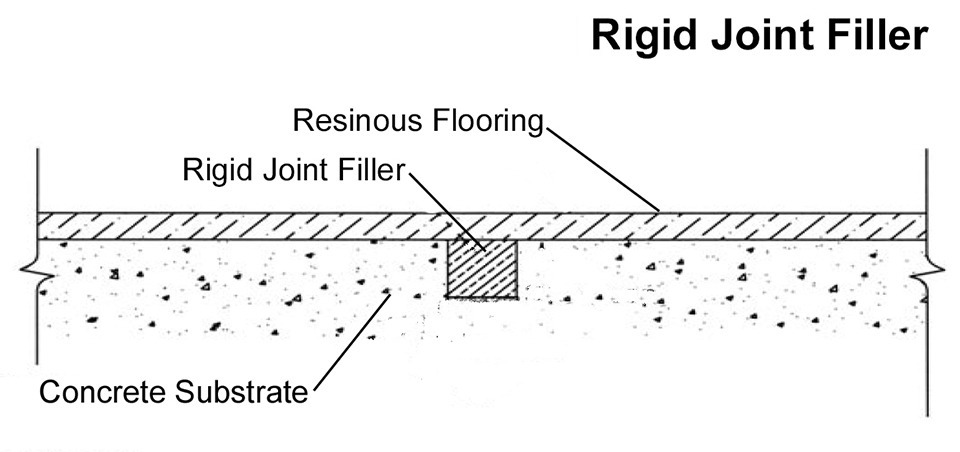

Rigid epoxy joint fillers are a mixture of 100% solid epoxy and an aggregate blend that simply patches a joint flush with the surrounding floors. Assuming the control joint will remain stationary, rigid epoxy joint fillers can produce a completely seamless floor system after the resinous flooring system is installed.

Companies also have two choices when it comes to expansion and control joints: installing new joint fillers or patching over existing joints. Patching is the more inexpensive option of the two, but not everyone is willing to roll the dice on possible future movement and the possibility of hairline cracking at the existing joint location. Most resinous flooring applications involve addressing floor joints at some point during the repair and installation processes, which is why our team can evaluate the level of damage or deterioration and recommend the best solution for your application.

PennCoat’s Floor Joint Repair System

This is an example of a Floor Joint repair for older industrial floors that have damaged and uneven floor joints that consequently will damage forklift tires and unsettle material handling carts.

Our process is to cut out the damaged uneven joint to sound concrete and infill the joint with a high wearing rigid epoxy mortar. When completed, the repair creates a flush transition between adjoining concrete slabs.

In the event of structural movement, this joint repair system will not prevent future cracking of the control joint. PennCoat also offers a less durable flexible joint membrane system that allows for lateral movement.

If the continuity and smoothness of your flooring has been compromised due to years of abuse from forklift traffic and heavy loads, joint filling can repair and protect the joint edges from damage that’s typically caused by heavy load pressure and the impact of hard wheels.

Why Choose PennCoat

If you’re looking to repair or replace floor joints and membranes for your existing flooring system, the flooring professionals at PennCoat can help. As an Avetta-trusted partner and ISN member company, our friendly team can answer any questions you may have, and we can work with you to develop a plan based specifically on your needs and budget. We know how frustrating unexpected repairs can be, which is why we can prep the area and perform the work with minimal impact to your business.

Ready to keep your flooring in tip-top shape to help your operation to run smoother and safer? Contact us today to learn more about our floor joints and membranes services or to schedule an appointment. We look forward to hearing from you!